The Essential Guide to Electric Motors for Beginners

Learn how electric motors work, the differences between AC, DC, stepper and servo types, key specs, control methods, and how to choose safely.

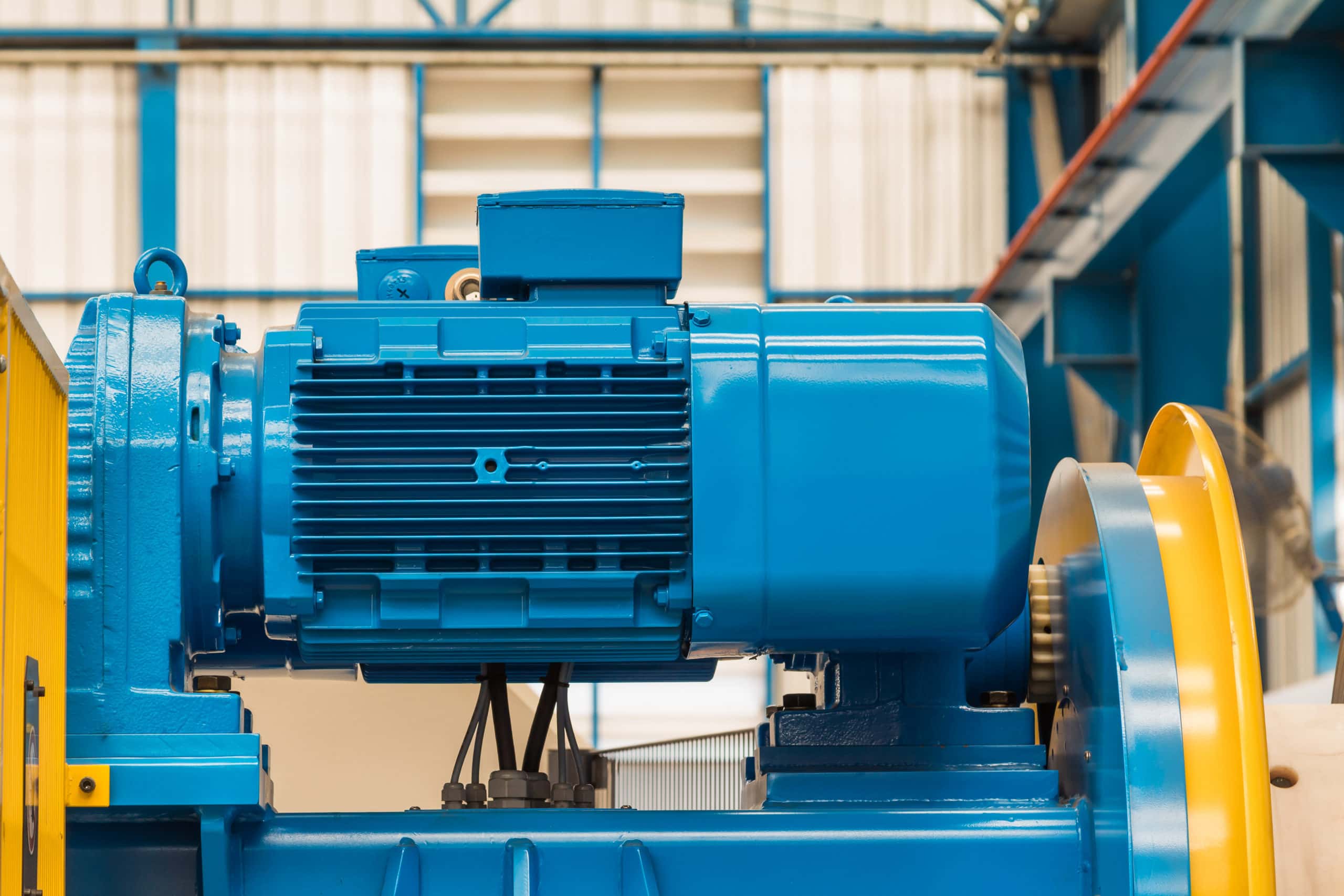

What Is An Electric Motor? An electric motor is a device that converts electrical energy into mechanical motion, turning electricity into useful torque and speed at a shaft. At its core are a stator (stationary part) and rotor (rotating part) that create and react to a magnetic field. That interaction produces rotational force, measured as torque, which drives fans, pumps, tools, and vehicles. Beginners should get comfortable with a few essentials: voltage is the electrical pressure feeding the motor, current is the flow that largely dictates torque, power (watts) is the product of voltage and current, and efficiency reflects how much electrical power becomes mechanical output. Motors are rated for a duty cycle (how long they can run at a given load) and a rated speed measured in RPM. Whether powered by DC from batteries or AC from mains, the goal is dependable motion. Understanding these building blocks will help you choose, control, and care for a motor safely and effectively.

Common Motor Types Electric motors come in several families, each with strengths. Brushed DC motors are simple and inexpensive, using carbon brushes to switch current in the rotor; they deliver strong starting torque but need maintenance as brushes wear. Brushless DC (BLDC) motors replace brushes with electronic commutation, improving efficiency, lifespan, and quiet operation, though they require a dedicated controller. AC induction motors are rugged workhorses for constant-speed duties; with a variable frequency drive they offer smooth, efficient speed control. Synchronous AC motors lock their rotor speed to the power frequency or a permanent magnet field, delivering precise speed or position. Stepper motors move in discrete steps for positioning tasks, often without feedback. Universal motors run on AC or DC and achieve very high speeds, common in compact tools. Choosing among them depends on required torque, speed range, control complexity, cost, noise, and maintenance expectations.

How Motors Produce Motion Motors rely on electromagnetism: current flowing through windings creates a magnetic field that interacts with another field to produce force. In DC designs, commutation switches current direction to keep the rotor turning; in brushed types this is mechanical, while BLDC uses electronics and sensors or sensorless back-EMF detection. In AC induction motors, the stator's rotating field induces currents in the rotor, creating slip—a small speed difference that enables torque. Synchronous motors synchronize the rotor to the rotating field, delivering constant speed. A few rules of thumb help beginners: torque is broadly proportional to current, while no-load speed tracks with voltage (DC) or frequency (AC). As speed rises, back-EMF opposes the supply, reducing current and torque. Every motor has a torque–speed curve that shows how performance changes under load, and starting or stalling can draw high inrush current. Understanding these dynamics guides safe operation and effective control strategies.

Reading Specs and Sizing Choosing the right motor starts with decoding the nameplate and datasheet. Key entries include rated voltage, current, power, torque, RPM, and efficiency. Also note duty rating (continuous or intermittent), service factor (headroom above rating), insulation class, ambient temperature, and IP rating for dust or moisture protection. Match the motor to your load profile: is it constant torque (conveyor), variable torque (fan or pump), or constant power over a range (tools)? Consider starting torque, peak torque, and acceleration needs; high-inertia loads may require a larger motor or a soft start. Use gear reduction to trade speed for torque and improve controllability at low speeds. Check frame size and mounting style for mechanical fit, and ensure your power supply can handle startup current. Proper sizing balances performance, thermal limits, and cost so the motor runs cool, efficient, and reliable without being oversized.

Controlling Speed and Torque Control ranges from simple to sophisticated. Basic on/off and reversing (by swapping DC polarity or AC phase sequence) may be enough for simple tasks. For DC motors, pulse-width modulation (PWM) adjusts average voltage efficiently, shaping speed and limiting current for torque control. Brushless DC motors use an ESC that sequences phases; advanced versions offer field-oriented control for smooth, high-torque operation. AC induction motors pair with variable frequency drives (VFDs), which vary frequency and voltage to regulate speed while protecting against overload. Closed-loop systems use encoders, resolvers, or Hall sensors to measure position or speed and apply PID control for precision and repeatability. Add soft start, current limiting, ramp profiles, and braking (dynamic or regenerative) for safety and performance. Mind EMI by using proper cabling, grounding, and filters, and ensure controllers match motor type, ratings, and application requirements.

Installation, Safety, and Care Good installation prevents most problems. Ensure solid mounting, accurate alignment, and the right coupling (flexible, belt, or direct) to avoid excessive vibration and bearing loads. Use correct wire gauge, secure terminals, and proper grounding; include fuses or breakers and follow lockout practices before servicing. Provide ventilation or cooling so the motor can shed heat, and keep air paths and fans clear of dust. For harsh environments, choose appropriate IP ratings and consider seals or enclosures. Routine maintenance includes inspecting bearings, checking lubrication, looking for brush wear and commutator condition in brushed motors, tightening fasteners, and listening for unusual noise. Monitor temperature, vibration, and current draw to catch issues early. Common faults include overheating from overload, misalignment, blocked airflow, or undervoltage; and electrical troubles like loose connections or insulation degradation. A simple checklist and regular intervals will keep your motor efficient, safe, and long-lived.

Smart Buying and Beginner Tips Start with a clear requirements list: available power supply (voltage, AC or DC), needed torque and speed range, duty cycle, environment, size limits, and noise targets. Compare efficiency, controller needs, and total cost of ownership—a pricier, efficient motor can save energy and maintenance. Look for complete datasheets, curves, and optional accessories such as gearboxes, encoders, and brakes. For prototypes, build a small test bench with a current-limited supply, multimeter, and tachometer to verify no-load speed, no-load current, and temperature rise. Avoid prolonged stall, respect current limits, and add fuses or electronic protection. Plan for wiring, mounting, and control early to prevent surprises, and document settings and results as you iterate. When in doubt, ask for application support, share your load profile, and request performance curves. A methodical approach yields a motor system that is safe, responsive, and reliable from the first spin.