Servo vs Stepper Motors: Which One Fits Your Application?

Compare servo and stepper motors by speed, torque, accuracy, cost, and control complexity to choose the right drive for your application.

Understanding the Basics: In the world of electric motion, two popular choices dominate conversations: stepper motors and servo motors. Both convert electrical energy into controlled movement, yet they differ in how they achieve position, speed, and torque. A stepper typically operates open-loop, advancing in discrete increments, which offers predictable positioning without sensors. A servo is a closed-loop system that uses an encoder and a controller to continually compare commanded and actual position, adjusting current to stay on target. This distinction shapes everything from responsiveness and efficiency to integration and cost. Steppers shine in simpler, budget-conscious applications that demand solid holding torque and moderate speeds. Servos excel when you need high dynamic performance, smooth motion, and reliable feedback under varying loads. Choosing between them means weighing load inertia, duty cycle, precision requirements, available control hardware, and the skill needed for tuning and maintenance. Understanding these fundamentals sets the stage for selecting the motor technology that truly fits your application.

Inside Stepper Operation: A stepper motor advances in fixed step angles, energizing stator phases in sequence to move the rotor one increment at a time. With microstepping, the driver modulates current sinusoidally to create finer command resolution and smoother motion, reducing vibration compared to full steps. Steppers deliver strong holding torque at standstill, making them ideal for indexing, positioning, and applications that must resist back-driving without constant motion. However, their torque-speed curve falls as speed increases, and excessive acceleration, load, or friction can cause missed steps in open-loop systems. Careful acceleration profiles, mechanical damping, and current settings help mitigate resonance and heat. Because steppers do not require encoders, they simplify wiring and lower cost, but they rely on conservative margins and often use homing routines to ensure positional certainty. For many tasks with moderate speeds, finite moves, and predictable loads, steppers provide reliable, repeatable motion with minimal control complexity.

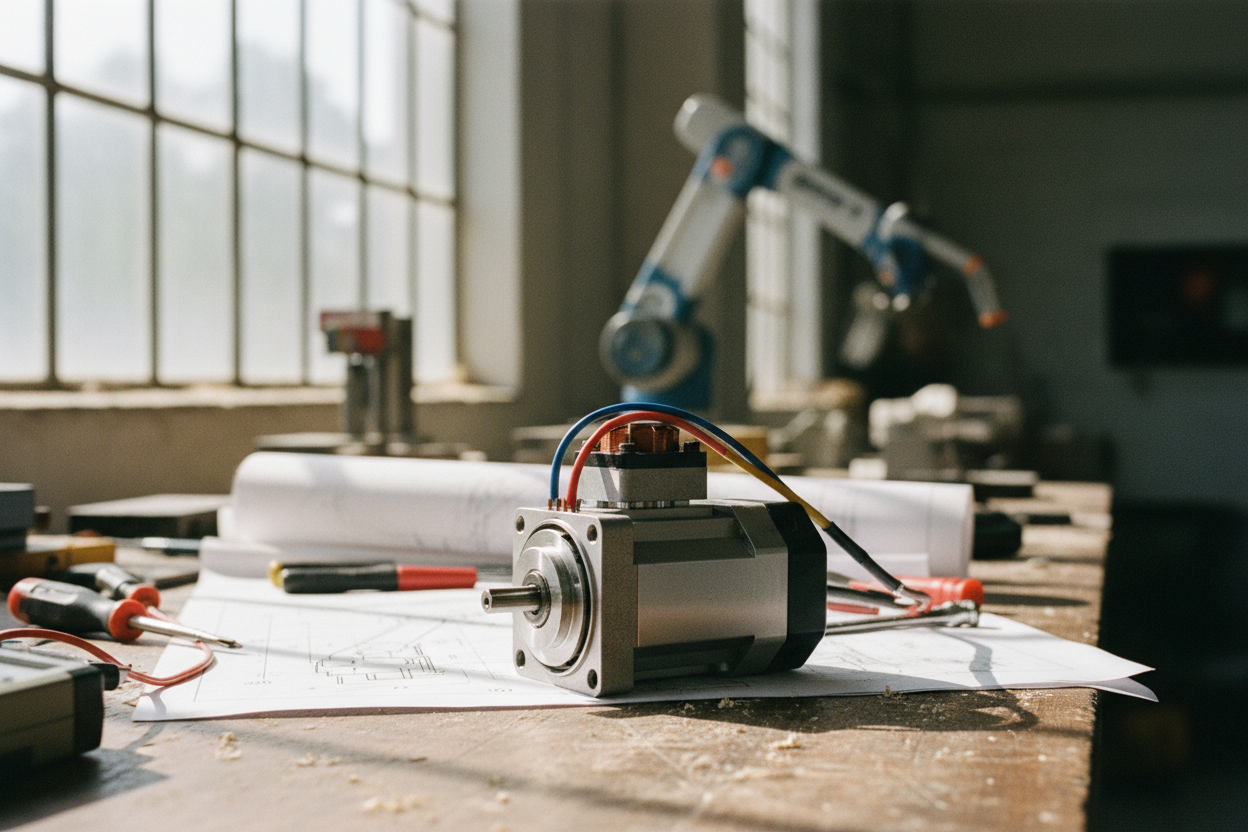

Inside Servo Operation: A servo motor pairs a motor (often brushless for efficiency and longevity) with an encoder and a drive that executes a closed-loop control algorithm, commonly PID. The drive continuously monitors position, velocity, and sometimes torque, adjusting current to match the command trajectory. This yields high torque at speed, excellent acceleration, and consistent performance across varying loads. Servos can deliver brief peak torque for demanding moves, maintain smooth motion through high bandwidth control, and minimize steady-state error. Achieving that performance requires proper tuning, inertia matching, and sometimes gearing to balance speed and resolution. When configured well, servos offer outstanding smoothness, low audible noise, and energy efficiency under dynamic conditions. They also provide fault detection, reporting following error, overcurrent, or overheating, which helps protect equipment. While the upfront hardware and integration effort can be higher than steppers, servos reward complex, high-throughput systems where repeatability, speed, and reliability are critical.

Performance, Accuracy, and Smoothness: Performance hinges on how each technology generates and verifies motion. Steppers have inherent step resolution, and microstepping enhances commanded granularity and smooths transitions, though real-world accuracy depends on load, stiffness, and driver linearity. Servos achieve accuracy through encoder resolution and tight feedback control, delivering superior repeatability across variable conditions. Mechanical backlash and compliance impact both, so the full system—motors, couplings, belts, screws, and frames—must be considered. In noise and vibration, steppers can exhibit resonance or buzzing near certain speeds, while servos generally provide quieter, fluid motion, especially at higher velocities. Regarding reliability, steppers may stall without clear indication in open-loop setups, whereas servos raise alarms when error exceeds thresholds. A hybrid approach, closed-loop steppers, adds encoders to stepper systems, improving torque utilization, stall detection, and thermal behavior while preserving stepper simplicity. Ultimately, the winning choice balances resolution, stability, thermal management, and the motion profile your application demands.

Integration, Cost, and Reliability: Integration touches hardware, software, and ongoing operations. Steppers typically use step/direction interfaces and straightforward drivers, reducing wiring complexity and controller demands. Servos may support richer control interfaces, including high-speed command protocols, absolute feedback, and advanced diagnostics, which can streamline commissioning in complex machines but increase initial setup. Cost considerations include motor, drive, power supply, encoder, cables, and mounting. Steppers often win on upfront cost, while servos can provide better throughput, energy efficiency under dynamic load, and uptime via fault reporting. In reliability, brushless servos minimize maintenance, whereas brushed variants require periodic brush replacement. Environmental factors—temperature, dust, vibration, and EMI—affect both technologies and may dictate enclosure class and grounding strategy. Thermal design matters: steppers can run hot at high holding current; servos regulate current to demand, reducing idle heat. Carefully plan cable routing, shielding, and grounding to avoid noise-induced errors and to sustain long-term reliability.

Choosing for Your Application: Start with a clear definition of your motion profile. Quantify load inertia, required torque at speed, linear or rotary travel, cycle time, precision, and duty cycle. Map mechanical choices—leadscrew, belt, gear reduction, or direct drive—to the motor's optimal operating region. If your application emphasizes cost, simplicity, and strong holding torque at modest speeds—like 3D printers, small CNC axes, table indexers, and dispensing—a well-sized stepper often excels. If you need high acceleration, tight tolerance, and smooth high-speed motion—such as in robot joints, fast pick-and-place, advanced machine tools, or packaging—a servo is usually the better fit. Consider closed-loop steppers when you want feedback and stall detection without fully switching to servo architecture. Always prototype, verify with torque-speed data, and validate thermal and stability margins. The right motor is the one that meets performance targets reliably within your budget and engineering capacity.