Safe Motor Wiring Practices for Hobbyists and Professionals

Learn essential motor wiring safety—from PPE and lockout/tagout to grounding, overcurrent protection, VFD tips, and testing—for hobbyists and pros.

Understanding Motor Basics and Safety Mindset: Safe motor wiring begins long before a screwdriver touches a terminal. Start by studying the motor nameplate and control documentation to confirm voltage, phase, current, power rating, and duty cycle. Identify the motor type—AC induction, brushless DC (BLDC), stepper, or servo—and understand how its control strategy (direct-on-line, starter, or VFD) influences wiring details. Build a safety-first routine: de-energize circuits, apply lockout/tagout, verify absence of voltage with a reliable multimeter, and wear appropriate PPE. Consider the installation environment: heat, moisture, dust, and vibration all affect cable selection, routing, and enclosure rating. Review schematics, terminal markings, and manufacturer notes to avoid assumptions. Plan conductor paths, protective devices, and labels before you cut a single wire. Determine where disconnects and test points will live so you can commission and service the system without improvisation. A disciplined preparation phase reduces rework, prevents hazards, and creates a foundation for consistent, professional-grade results in the motors category.

Selecting Proper Cables, Connectors, and Tools: Choosing materials wisely is central to reliability. Match wire gauge to expected current and distance to control voltage drop, and select insulation for the temperature, chemical exposure, and flexibility the application demands. Favor stranded conductors for vibrating machinery and use recognized color conventions for line, neutral, protective earth, and control circuits. For terminations, prefer quality ring lugs, spade lugs, or ferrules crimped with the correct die; avoid generic hardware-store crimpers that yield weak connections. Use torque screwdrivers or wrenches to meet manufacturer specs on terminals and lugs. Integrate proper strain relief with glands or cord grips, and route cables in conduit or cable trays sized for fill and heat dissipation. Keep a calibrated multimeter, clamp meter, and, when appropriate, an insulation resistance tester on hand. Label both ends of every conductor with heat-shrink markers and maintain a living wiring diagram so anyone can trace circuits confidently later.

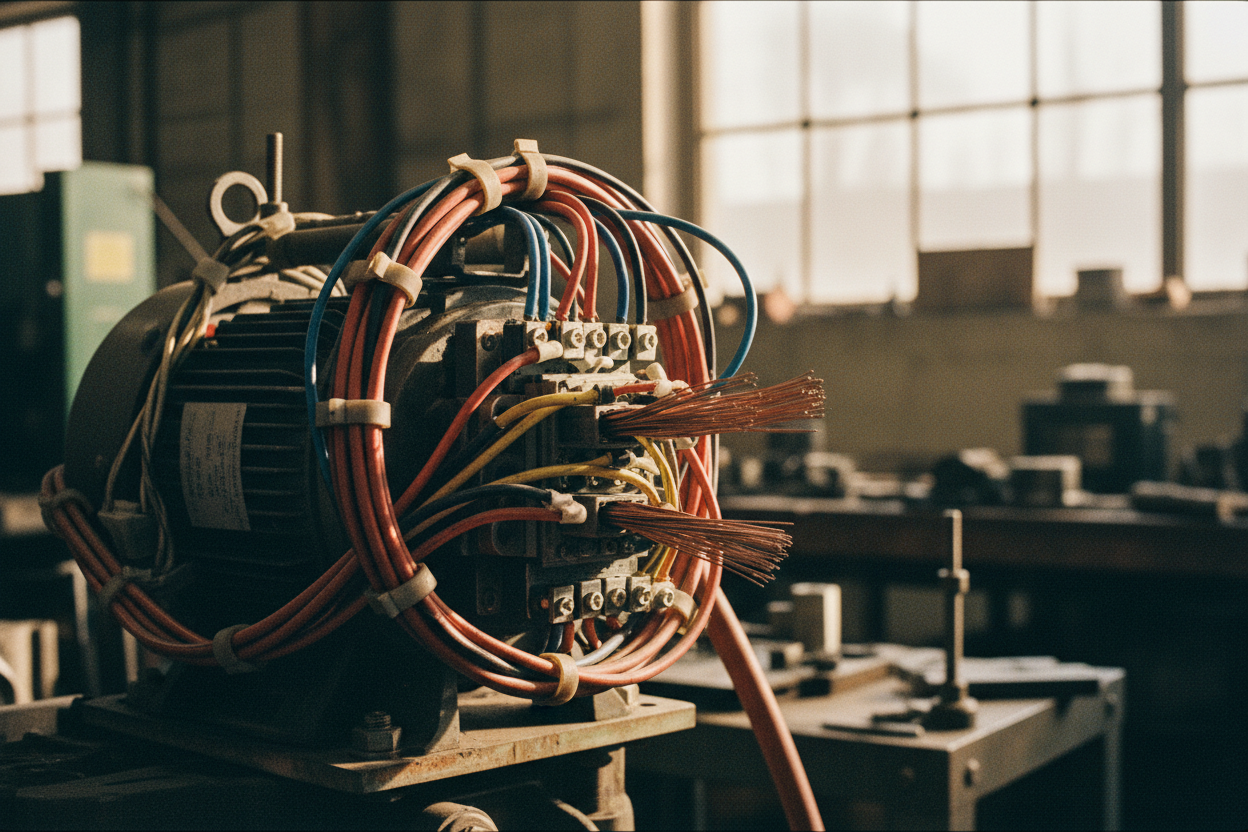

Routing, Terminations, and Mechanical Integrity: Good wiring is as much mechanical as it is electrical. Separate high-current motor leads from low-level control or sensor wiring to minimize EMI, crossing at right angles when paths must intersect. Observe minimum bend radius, support conductors with clips or ties that do not crush insulation, and avoid sharp edges that can abrade jackets. At the motor junction box, provide strain relief and adequate slack for service loops while keeping covers easy to close. Prepare conductors carefully: strip to the correct length, avoid nicking strands, and insert ferrules for clamp-style terminals. Use the correct crimp profile and perform a gentle pull test to verify integrity; do not rely on solder in high-vibration environments where solder wicking can cause fatigue. Tighten terminals to specified torque and consider two-hole lugs on larger conductors for stability. Maintain creepage and clearance distances, keep terminals clean, and finish with tidy, readable labels that match the documented schematic.

Grounding, Bonding, and Protective Devices: A robust grounding and bonding scheme protects people and equipment. Connect an appropriately sized equipment grounding conductor (EGC) directly to the motor frame and verify continuity from source to load. Bond enclosures, raceways, and cable trays so fault currents have a low-impedance path. Size overcurrent protection—fuses or circuit breakers—to the motor's characteristics, and include thermal overload relays or electronic motor protection to guard against sustained overcurrent and stalled conditions. Use a properly rated disconnect within sight of the motor for maintenance safety. When applying variable frequency drives (VFDs), choose shielded motor cable, terminate shields correctly to control EMI, and follow the manufacturer's recommendations for filters and grounding. Recognize that certain ground-fault protective devices may be sensitive to leakage currents from drives; select equipment accordingly. Verify enclosure ratings and gasketing for the environment, ensuring that all metallic parts remain bonded for durable, predictable fault performance.

Pre-energization Checks and Commissioning: Commissioning is where planning proves itself. With power isolated, confirm every termination against the wiring diagram, then perform continuity and insulation resistance tests to expose misconnections or compromised insulation. On three-phase systems, validate phase sequence and motor rotation with a brief jog or a phase rotation meter; swap two phases to correct direction if needed. For DC motors, verify polarity and observe initial current draw. Set overload devices, time delays, and protective thresholds per the motor's data. Energize in stages: power the control circuit first, confirm interlocks and emergency stop function, then apply line power while monitoring inrush, running current, and voltage at the terminals. Listen for unusual noise, feel for excessive vibration, and spot-check temperature rise. For VFD installations, program acceleration ramps, current limits, and carrier settings to balance performance and acoustics. Record baseline readings and label final settings so future maintenance has clear reference points.

Maintenance, Troubleshooting, and Documentation: Reliability is sustained through routine care. Schedule periodic inspections to recheck terminal torque, look for corrosion, and assess signs of overheating like discoloration or brittle insulation. Verify strain relief integrity, inspect cable glands for sealing, and clean dust that can trap heat. Use thermal imaging to identify hotspots and a clamp meter to trend current against baseline values. Keep as-built schematics, parameter lists, and change logs up to date so diagnostics are swift and accurate. When faults occur, start with protective device status, then measure winding resistance, insulation resistance, and supply voltage under load. For control issues, isolate segments methodically and confirm sensor and relay operation. Replace damaged connectors rather than reusing questionable hardware. Always de-energize and apply lockout before touching conductors, even during quick checks. Stock quality lugs, ferrules, and fuses to avoid compromises. Knowing when to escalate to a qualified professional is itself a hallmark of safe, professional motor wiring practice.