Motor Efficiency Explained: How to Save Energy and Costs

Learn how motor efficiency works, what drives losses, and practical steps to cut energy use, downtime, and lifecycle costs in any facility.

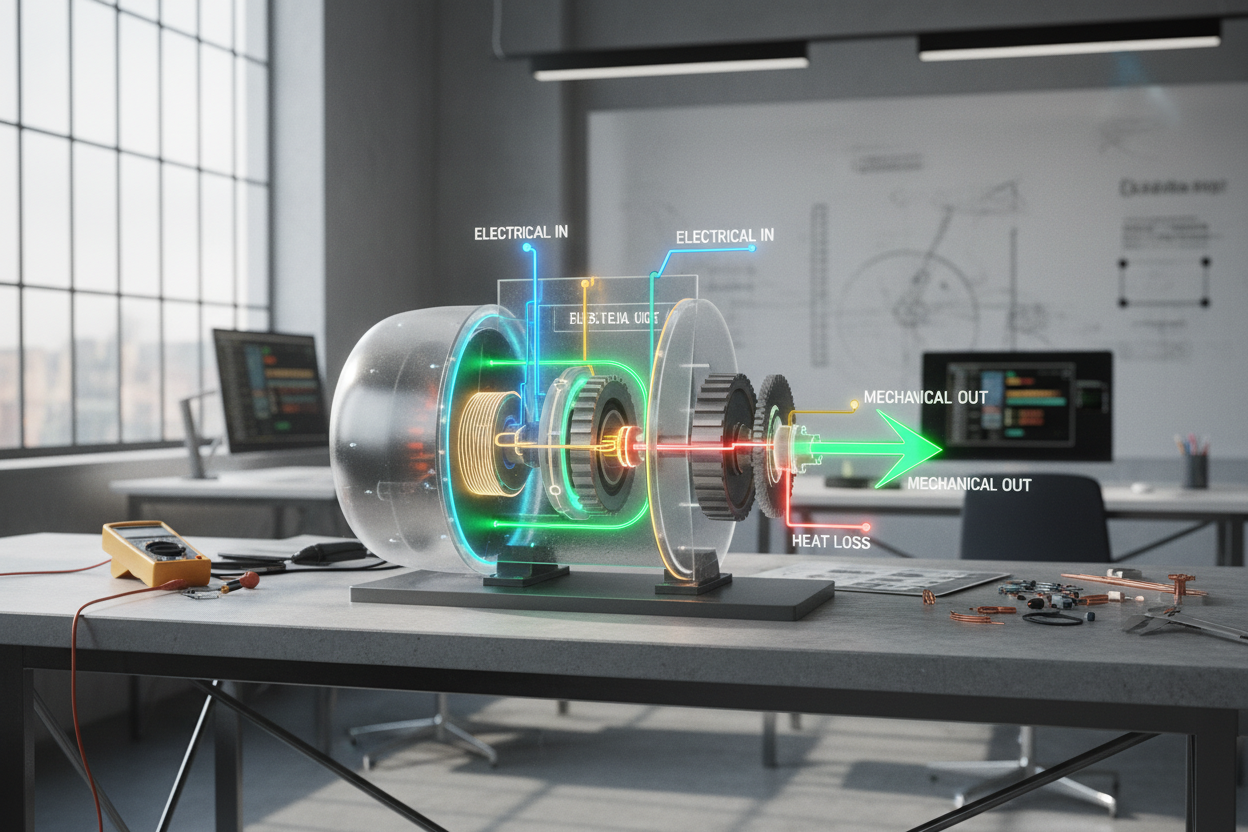

Fundamentals: At its core, motor efficiency is the ratio of useful mechanical output to electrical input, indicating how well a motor converts energy into work. Losses reduce this ratio and typically include stator and rotor copper losses, core (iron) losses, friction and windage, and stray load losses. Efficiency isn't static; it varies with load factor and duty cycle, usually peaking within a certain operating band. Running motors significantly underloaded can push them into less efficient regions, wasting energy and generating unnecessary heat. Application specifics matter: torque requirements, start-stop frequency, ambient temperature, and ventilation all shape performance. Understanding the torque-speed profile helps match the motor to the job so it spends more time near its optimal range. A well-selected, properly applied motor reduces electricity use, trims cooling demands, and improves reliability. Over continuous operation, even small percentage gains compound, lowering life-cycle cost and easing the strain on electrical infrastructure while delivering steady, predictable output.

Right-Sizing: Selecting the correct motor is one of the fastest paths to saving energy and costs. Oversizing seems safe, but at light loads it often reduces part-load efficiency, increases purchase price, and encourages energy waste. Undersizing forces overheating, nuisance trips, and premature wear. Evaluate the application's torque-speed curve, typical and peak loads, start-up demands, and duty rating to determine the correct frame and power. Consider service factor, ambient conditions, and enclosure type to keep temperature rise in check. Mechanical transmission choices also affect sizing: gear ratios, belt drives, and couplings impose losses and inertia that the motor must overcome. When selecting among technologies, compare efficiency at likely operating points, not just at nameplate rating. Think system: a motor that allows simplified mechanics or a more direct drive can reduce overall losses. Proper right-sizing aligns the motor with real-world demand, helping it run in its sweet spot and delivering dependable performance with less energy.

Smart Control: Intelligent control turns decent hardware into a high-efficiency system. Variable frequency drives (VFDs) align speed with demand, especially for pumps and fans where the affinity laws make small speed reductions yield large power savings. Soft starters reduce inrush and mechanical stress, while VFDs enable ramp profiles, PID control, and precise setpoint management that smooth out peaks and trim waste. Look beyond speed: use sensors and feedback to avoid over-delivery, cycling, or deadband conflicts. Where constant speed is necessary, consider energy-optimized control strategies that minimize unnecessary torque. Account for electrical side effects like harmonics and electromagnetic interference, applying filters or appropriate cabling when needed. Keep the drive's environment cool and clean to protect components and preserve efficiency. When marrying motors to controls, confirm turndown capability, minimum speed limits for cooling and lubrication, and stable operation across the load range. Smart control tightens process stability, reduces wear, and converts energy into output more predictably and economically.

Maintenance: Preventive maintenance is a hidden efficiency lever. Clean, cool motors experience lower I²R losses and extended insulation life, while dirty or obstructed cooling paths drive temperatures up and efficiency down. Keep airways clear, verify ventilation, and maintain proper lubrication intervals to minimize bearing friction. Precision alignment and correct belt tension reduce mechanical losses and protect seals and shafts. Monitor electrical health by checking connections, tightening terminals, and measuring voltage imbalance and current imbalance, which accelerate heating and inefficiency. Use condition monitoring tools—vibration analysis, thermography, and motor current signature analysis—to identify issues before they become costly failures. Replace worn couplings and ensure the driven equipment is operating smoothly; a misbehaving pump, fan, or gearbox can drag down motor performance. Maintenance is not just about uptime—by minimizing friction, heat, and rework, it directly improves efficiency, stabilizes processes, and prolongs the productive life of both motors and the systems they power.

Power Quality: Healthy power quality sustains efficient operation. Poor power factor forces higher current for the same work, increasing I²R heating and utility demand charges, so consider power factor correction using capacitors or appropriate compensation strategies. Voltage imbalance and sag cause uneven heating and torque pulsations that degrade motor efficiency and lifespan. Harmonics from nonlinear loads can raise losses in motors and transformers; mitigate with line reactors, filters, or harmonic-aware drive settings. On the mechanical side, reduce parasitic losses: align shafts, minimize unnecessary gear stages, and evaluate opportunities for direct drive or higher-efficiency gearboxes. Select efficient transmission components and maintain proper belt selection and tension. Optimize wiring and conductor sizing to reduce distribution losses, and plan conduit runs to limit heat buildup. System-level thinking matters: improving ductwork, piping, or process controls can lower required torque and speed, enabling a smaller, more efficient operating envelope for the motor and its drive.

Measure & ROI: You can't improve what you don't measure. Establish an energy baseline using kWh, current, voltage, and load profile data, then track energy intensity metrics (such as kWh per unit of output). Smart meters and data loggers reveal patterns like idle running, peak demand spikes, and throttling losses ripe for correction. Pair findings with actionable changes: VFD tuning, right-sizing, maintenance, and power quality improvements. Quantify benefits with total cost of ownership (TCO) and payback analyses that include energy, downtime, product quality, and maintenance savings. Document standard operating procedures so optimized settings persist through shifts and seasons. Update procurement specifications to favor high-efficiency motors and compatible controls, ensuring future assets align with your energy goals. Share results to build engagement; operators who see saved energy translated into stable processes and fewer breakdowns reinforce good practices. Continuous measurement turns isolated upgrades into a durable, compounding efficiency strategy.