Cooling Methods for High-Performance Motors

From air and liquid systems to direct winding and rotor cooling, explore proven methods to keep high-performance motors efficient and reliable.

Thermal Basics. High-performance motors convert electrical energy into mechanical output, and the gap between input and output becomes heat. Primary sources include Joule losses in windings, core losses from hysteresis and eddy currents, and mechanical losses like friction and windage. Managing this heat protects insulation systems, preserves magnet integrity, and stabilizes bearing lubrication. Effective cooling begins with a clear thermal path: from copper and steel to the frame, then to the ambient. Designers map heat flux and identify bottlenecks such as poor contact interfaces, thick varnish layers, or stagnant airflow zones. The goal is to maintain temperatures below material limits while minimizing pressure drop, power draw, and noise from cooling hardware. A holistic approach balances efficiency, size, and reliability, considering the duty cycle, enclosure constraints, and environmental cleanliness. With a sound grasp of where heat originates and how it travels, the right blend of conduction, convection, and radiation can be selected to keep a motor operating in its optimal thermal envelope.

Forced-Air Strategies. Air cooling remains a versatile, cost-effective approach when power density is moderate and airflow access is available. Performance hinges on promoting forced convection across fins and hot surfaces while avoiding recirculation. Axial fans offer compact flow with lower pressure capability, whereas centrifugal blowers deliver higher static pressure for ducted or baffled paths. Shrouds and flow straighteners guide air over fins with proper spacing to disrupt the boundary layer without excessive backpressure. Surface treatments and fin geometries can encourage turbulent mixing that raises heat transfer coefficients. In contaminated environments, filters and debris screens protect passages but require maintenance to prevent clogging that undermines cooling. Designers consider vibration, acoustic limits, and electromagnetic compatibility when locating fans near the motor and drive. Thoughtful ducting, sealed interfaces, and thermal isolation from hot exhaust streams ensure cool intake air, enabling reliable temperature control with minimal parasitic losses.

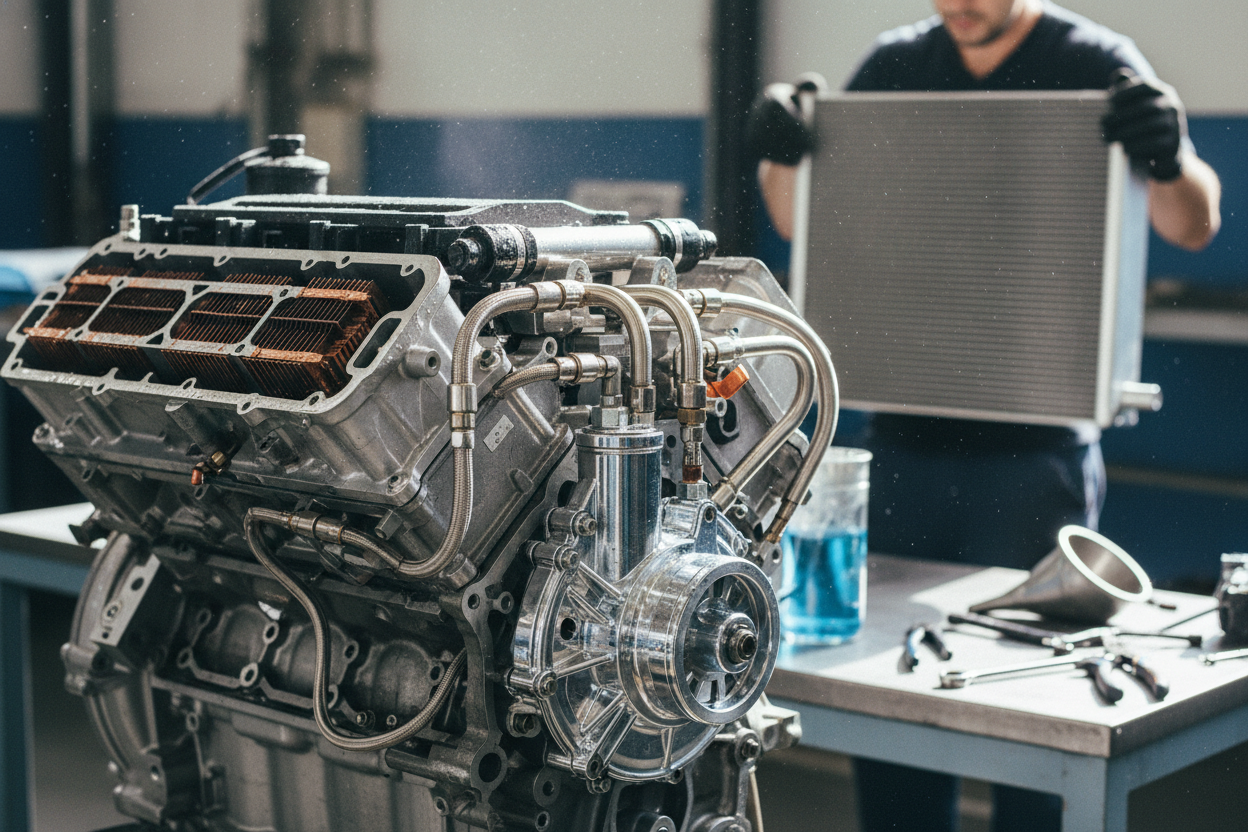

Liquid-Jacket Systems. When greater heat flux demands arise, liquid cooling provides a step change in performance. A coolant jacket integrated into the housing or stator frame channels fluid around hotspots, exploiting the high specific heat of liquids to remove energy efficiently. Channel design balances turbulence for heat transfer against pressure drop that drives pump power. Even distribution via manifolds prevents local hot spots, while air bleed provisions ease commissioning. Material choices and corrosion control are crucial; compatible alloys, inhibitors, and proper conductivity management extend service life. For applications near live conductors, dielectric coolants add electrical safety at some cost to thermal performance. Quick-servicing features like quick-disconnects and service ports support maintainability. Successful systems integrate sensors for flow and temperature, fail-safe logic, and derating strategies if flow degrades. With robust sealing, leak detection, and clean fluid, a jacketed design can support high continuous power while preserving compact motor dimensions.

Direct-Contact Cooling. Pushing thermal limits further often requires extracting heat at its source through direct-contact methods. Oil spray or immersion cooling bathes windings and end turns, collapsing thermal resistance between copper and coolant. Impingement jets target end-winding hot spots, while carefully designed slingers and returns minimize churning losses. Some rotors employ internal passages or a hollow shaft to circulate coolant, pulling heat from rotor bars, magnets, or sleeves that are otherwise hard to cool. Fluid selection prioritizes dielectric strength, viscosity, and thermal stability, and attention to aeration, foaming, and contamination control preserves performance over time. Sealing and shaft labyrinths contain fluid without excessive drag. Because direct-contact systems can elevate hydraulic power and introduce complexity, they pair best with high-duty applications where thermal margins unlock meaningful gains in torque density, overload capability, and cycle life.

Advanced Heat Transport. Heat pipes and vapor chambers enable efficient, passive relocation of heat from crowded zones to generous heat sinks. These two-phase devices exploit liquid-vapor phase change and a wick structure to deliver very high effective thermal conductivity with minimal temperature gradient. In motors, they can bridge from stator teeth or power electronics to finned surfaces or liquid-cooled plates, smoothing hot spots and enhancing transient response. Orientation-aware designs address gravity effects, while robust envelopes and compatible working fluids ensure durability. Complementary phase-change materials (PCMs) provide short-duration thermal buffering during bursts, absorbing peaks and allowing smaller steady-state coolers. Integrating these elements requires careful contact pressure, TIM selection, and structural support to survive vibration. When paired with smart control, advanced transport mechanisms reduce peak temperatures, limit thermal cycling, and create headroom for aggressive load profiles without resorting to oversized active cooling hardware.

Materials and Geometry. The shortest path to cooler motors is improving conduction between heat sources and the case. High-performance thermal interface materials (TIMs), potting resins with thermally conductive fillers, and graphite or ceramic pads reduce contact resistance while maintaining electrical isolation. Optimized impregnation enhances winding contact to the stator, shrinking hot spots in slot bottoms and end turns. High-conductivity slot liners, tooth tips, and end-winding spreaders steer heat toward designed sinks. Geometries with efficient fin density, adequate fin thickness, and clear air paths extract more heat per unit area without undue pressure drop. Attention to CTE matching and bond-line thickness avoids stress and delamination that degrade thermal paths over time. Manufacturing methods like additive fabrication enable internal channels, lattice fins, and integrated cold plates that were difficult with legacy processes. By reducing thermal resistance at every interface, designers unlock the full potential of whichever active cooling method is chosen.

Monitoring and Integration. Cooling works best when paired with intelligent thermal monitoring and control. Embedded RTDs, thermistors, or fiber-optic sensors track temperatures in windings, end turns, and bearings, while the drive estimates stator and rotor thermal states with model-based observers. This data supports derating, fan or pump speed control, and fault handling that prevents thermal runaway. Reliability hinges on predictable maintenance: cleaning fins, checking filters, verifying duct seals, inspecting fan bearings, flushing coolants, and confirming flow rates. System-level integration considers EMI, vibration, and service access so cooling hardware remains effective over the motor's life. Thoughtful commissioning validates temperature maps against expectations, catching misrouted ducts or trapped air. Finally, designers weigh weight, noise, and energy overhead of cooling against performance gains, selecting a balanced solution that keeps high-performance motors cool, efficient, and ready for demanding duty cycles.